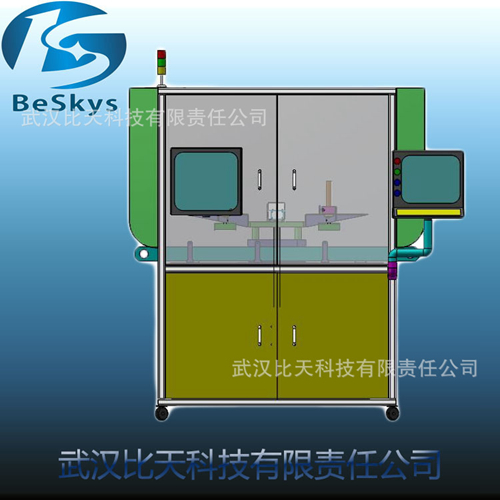

| Brand: BeSkys |

Model: BS-VSOD |

Product alias: Flight marking machine |

|

Uses: laser on-line processing |

|

|

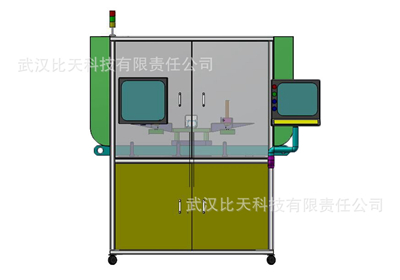

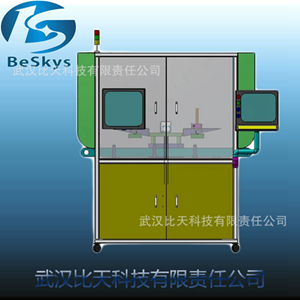

Product description

We designed and developed a set of industrial computer, high-speed industrial camera, sensor galactic flight visual dynamic processing system, without adding any fixture or guide device, for the field of view of the workpiece automatically identify and accurately correct the location to achieve Automatic processing, in the transmission speed of 250mm / s line to achieve accurate positioning processing, and in the posterior channel can be optional visual inspection, to achieve unattended processing line.

The main interface of the software includes image display area, processing file preview area, working parameter editing area, status display area and processing control area. Menu bar includes: camera settings, visual calibration, visual template, parameter settings, detection unit, save parameters and other menus. Among them, the detection unit for the expansion of the processing after the detection link to ensure that the output line of the product yield of 100%.

Features

The system has the advantages of easy to use, high degree of automation, strong functional relevance, safe and stable operation and so on.

1) the use of machine vision to identify the dynamic objects on the assembly line and positioning, in ensuring the accuracy of processing while improving the production efficiency;

2) extended visual inspection function instead of manual detection, to ensure that the output rate of this station is 100%;

3) a key to start processing, the system automatically identify objects and automatic processing, to achieve full automation;

4) use the queue to store the workpiece information, to achieve high-density workpiece processing;

5) single view to support multi-template multi-target search, processing files and visual templates free to match, easy to choose processing;

6) to support a variety of user permissions to ensure that the software specification operation and normal use;

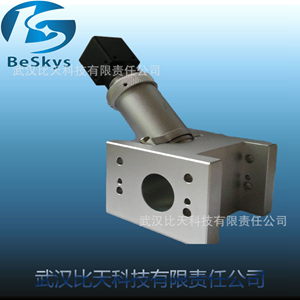

7) make full use of galvanometer control card hardware and software functions, high system integration;

8) Record and print the machining process in detail.

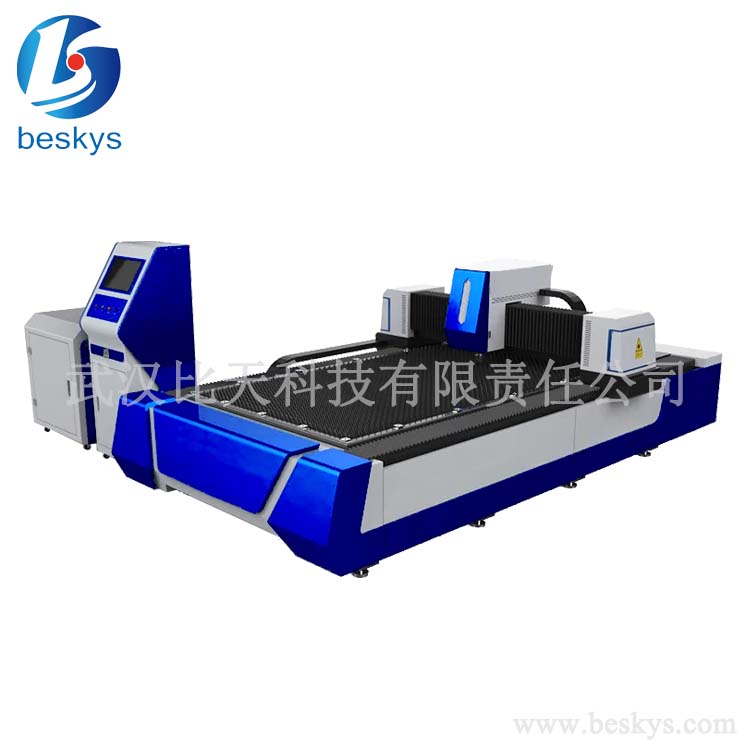

Product real shot